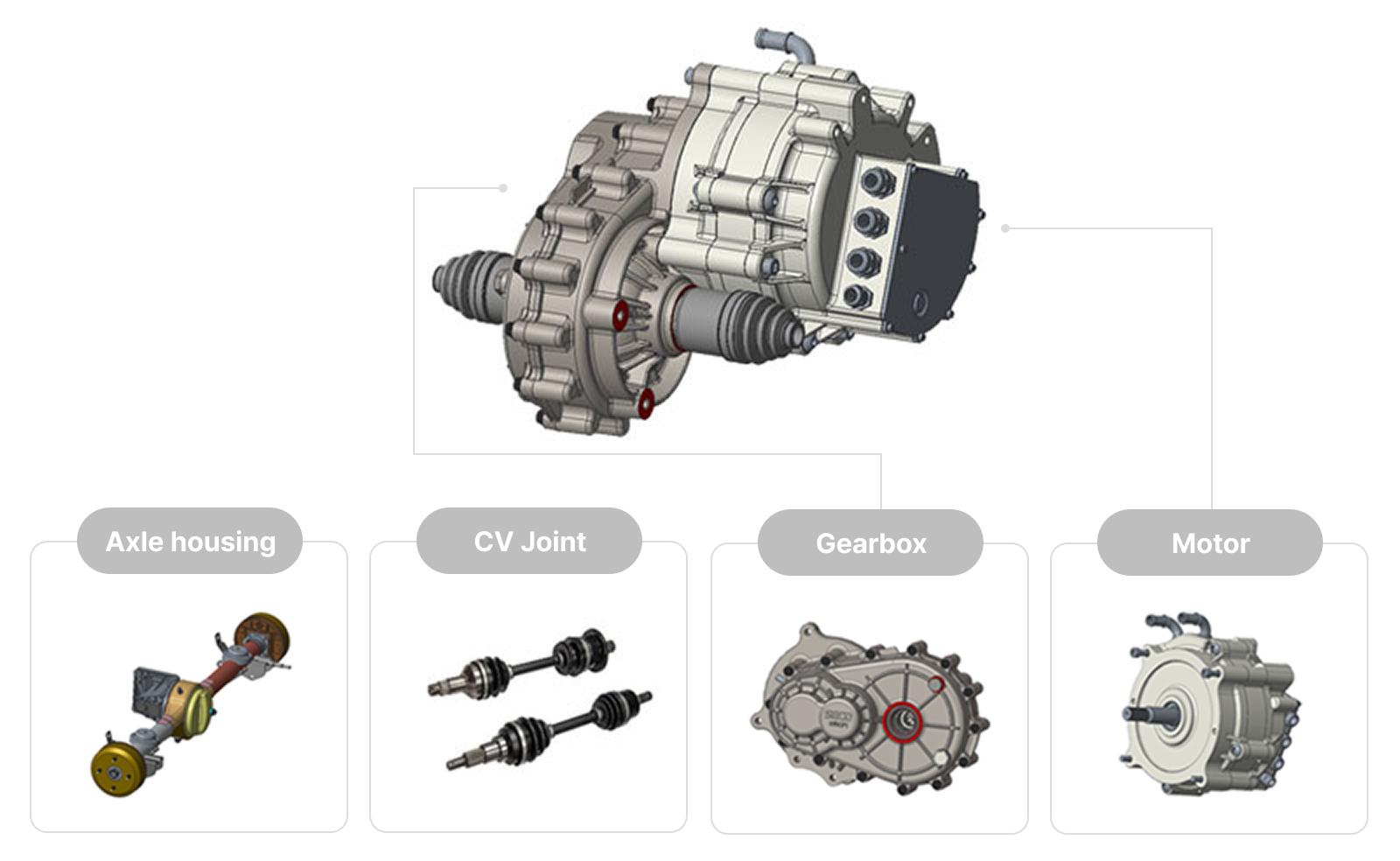

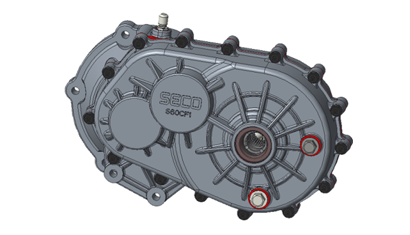

CV-JOINT TYPE reduction gearbox

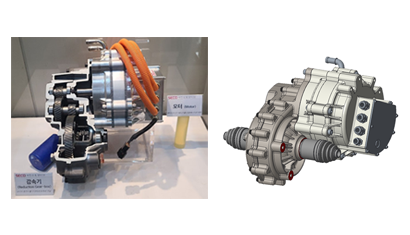

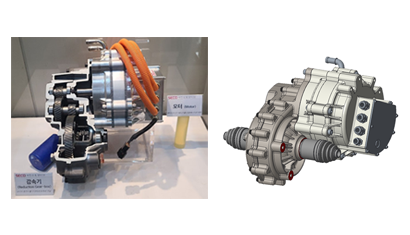

Offset type of reduction gearbox utilized with Helical gear Improvement on NVH by applying Grinding Gear

-

S15CF1(15kW)

-

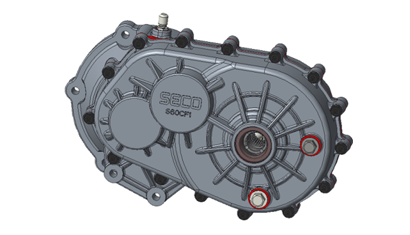

S60CF1(60kW)

We analyze the loadability of vehicle and customer’s requirement to match their most

desirable EV reduction gearbox system.

We design a gear train, NVH, case and lubrication system.

Also we evaluate the vehicles through dynamo.

With these methods we can make the optimized reduction system for electrical vehicle.

Offset type of reduction gearbox utilized with Helical gear Improvement on NVH by applying Grinding Gear

S15CF1(15kW)

S60CF1(60kW)

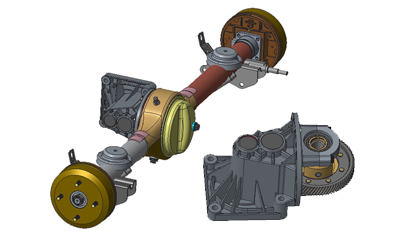

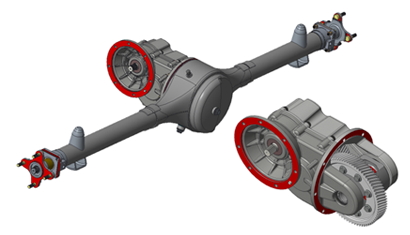

Applied high quality gear through optimized gear design and analysis

Confirmed solidity of axle housing with structural analysis and ridge test

S15AR1(15kW)

S80AR1(80kW)

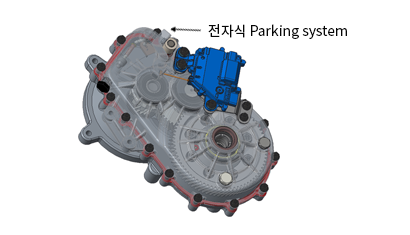

All the parking components can be settled and organized in narrow space with one

shaft.(patent reg.)

Depend on each vehicle’s layout, It can be equipped through structure

change

We can design suitable specification of Electric Drive System

which match customer’s request.

SECO’s Electric Drive System provides you the durability, high

performance, maintenance convenience and design flexibility.